By Araceli Gonzalez | November 18, 2020

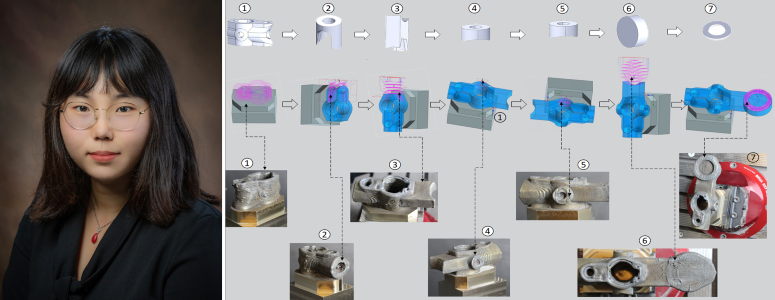

Dr. Xinyi Xiao (Mechanical Engineering '14) and her research work

In Fall 2020, SFSU Engineering alumna, Dr. Xinyi (Serena) Xiao, joined the Department of Mechanical and Manufacturing Engineering at Miami University, Ohio, as a tenure-track assistant professor. Dr. Xiao obtained her BS in Mechanical Engineering from SFSU, and her MS and PhD from Pennsylvania State University. This appointment makes Dr. Xiao the first SFSU Engineering alumni to be appointed a tenure-track faculty at a university. The School of Engineering at SFSU is immensely proud of our alumna for all of her accomplishments! Two student assistants from the School of Engineering had the opportunity to sit down and talk with Dr. Xiao, where she highlighted some of her favorite memories during her undergraduate years at the Station Cafe on 19th Ave and working in Dr. Kwok Siong Teh’s research lab!

Why did you decide to pursue a field in engineering? And when did you know engineering was the right fit for you?

“I decided to do engineering when I was really young. And the other reason that I chose engineering as my lifelong career is that I like to solve problems - especially hands-on problems that haven't been done before. The area that I want to continue to work on is to fully automate a lot of manufacturing processes.

“When I was young, I was trying to make all these things to be automated, like robotics, and I think that's kind of the reason why I chose mechanical engineering to be the area. I felt that engineering problems were appealing to me. And I really like to find solutions and tackle problems when I was young, and mechanical engineering was the most fitting for me. My father was doing mechanical engineering as well but his area is more in marine infrastructures, e.g. cranes at ports. So when I was really young, I saw him testing the vibrational responses of heavy, large cranes. And they try to reduce the vibrations in order to keep everyone safe. It may sound weird, but such tests were really interesting because cranes were really heavy machines, just like Transformers so I was really fascinated. That’s the pull for me to choose mechanical engineering”.

What did you enjoy most about working with Dr. Teh, in his lab at SFSU?

“He is a really, really, really nice guy. He has a good temper and he really cares about and dedicates himself to the students. My research area is additive manufacturing, which includes 3D printing technologies. Actually, the main reason why I chose additive manufacturing as my main research is partially because of Dr. Teh. At the time that I was working in his lab, he purchased an early stage 3D printer, which opened my eyes to the whole new world of 3D printing. Right now, 3D printers are relatively cheap - you can purchase one for $200 online. But at that time, like 6 or 7 years ago, 3D printers were quite a novelty. To create a simple cubic structure, it would take a really long time. But the process was really interesting. It's like you're trying to extrude your material by changing the state from solid to liquid then back to solid state again, for materials ranging from plastics to metals. The intriguing process motivated me to later pursue a research career in this area”.

Were you a part of any orgs during your time in school? How did they play a part in your academic career?

“I wasn’t part of any organizations when I was at SF State. But, later when I went to graduate school, I did join some Women in Engineering clubs. One of the reasons was, I didn’t spend a long time at SF State. I was an exchange student in my third year when I first came to SFSU. So, I was busy finishing all my courses and then after I fully transferred to SFSU, I had to complete some English and arts classes. So, I didn’t have enough time to join any organizations. It was actually a sad thing that I didn’t join any orgs at that time.”

Now that you’re a professor, do you see the activity from all the organizations and how they interact? Is it similar to what you experienced in grad school?

“Right now we’re in hybrid mode. So, half of it is going to be in person, and the other half of it is going to be online. But for next semester we’re pushing forward to in-person activity. So for now, I'm teaching the classes that require students to attend the lab in person. But for the lecture, we’re doing that virtually.

“I was thinking about the issue of women in engineering at this time, because our university also faces the same challenge - we have a low proportion of female engineering students. So we were attracting more girls in engineering majors, especially for mechanical engineering. Our university is actually famous for its manufacturing area, especially additive manufacturing. Right now, I have two female undergrad students and they are both doing well. I will encourage them to give a talk at next semester’s class, to make them the role models for the younger generation. They will tell the younger students how interesting this area could be and what's their prospective future in this area.

Since you’ve seen 3D printing in its early stages up until what it is now, what was the biggest or most revolutionary advancement? Today, 3D is very fast and accurate, where you can create good products for a fraction of the time. What do you think made the big switch?

“In the early stages, people used 3D printing as a prototyping technique. Their main concern was the shape of the object, less about its functionality. If the shape matches the design, that's good enough. These days, most of the 3d printers can easily achieve that. The main challenge now is to print functional parts that can be used in engineering applications, regardless of the print materials -- plastic, metal, ceramic or biomaterials. We want to make sure the mechanical property, tensile strength, and yield strength satisfy all the predefined requirements. We can print bio cells in order to replicate the person’s organs, ears, or skins. My research is mostly in additive manufacturing process to print large, heavy metal components. For example, to repair a turbine blade using traditional 3D printing may take a long time and waste quite a bit of materials. New additive manufacturing process would be able to rapidly fix the geometry of existing part without printing an entirely new part. So it's like removing the broken part and then trying to add more materials within the specific volume. It’s similar to a fast manufacturing production cycle, and it also ensures the functionality of the geometry in a cheaper manner.”

Why did you pursue a career in engineering education with your new position as an Assistant Professor?

“First of all, I like interacting with people as well as doing research. These days, to do good research, you cannot just do it by yourself. You need to build a team. You need to let more people join your area and appreciate what you’re doing. So that's the major reason that I wanted to be an educator. It’s important to teach students, let them learn the basic knowledge, slowly develop an interest in a particular area. As long as they have interest, they will have their own thoughts in developing new solutions. Teaching is the necessary step in getting students interested in doing research. This way, you can attract more people to join your effort, your team, and this is how you build a large team to tackle one important problem”.

Have you seen any students that have really sparked interest in the classes you have been teaching?

The class I'm teaching right now is about additive manufacturing. And all the students are really interested in this process because we do have plastic or metal 3D printers in our university. Those students have already learned about the traditional manufacturing of casting or forging in previous classes. When I talk about additive manufacturing, they would show a lot of interest because rather than removing materials, additive manufacturing is about adding materials. And through this process you can obtain better geometry than the other traditional processes. So most of the students in the class are very interested in this new topic. For this reason, I was able to recruit two students from my class to do research as they are really interested in the topics”.

How did your college experience prepare or help you in your career?

“I transferred to the U.S. when I was 20 years old and I learned a lot when I was at SF State . San Francisco is a really special and welcoming place because it's the first place I set foot in in the United States. At SFSU, I learned all about American cultures, and the differences in how engineering is taught in American universities versus Chinese universities. San Francisco has taught me a lot in terms of the differences and similarities of the cultures in America and China. And also, thanks to Dr. Teh, he provided the undergraduate research opportunity that brought me into my current research area. I still have many good friends in San Francisco.”

What is one piece of advice that you would give to your younger self?

“Join more groups, join more organizations. When you join more organizations you will be exposed to more people and broaden your social network. When you communicate more with others, you not only learn about their perspectives but also their experiences -- whether it's about research or life. Through such exchanges, you will hear different opinions and that helps to build your insights as well. Whether it is in academia or industry, I think being part of a strong network is really important. And, by building network, I don’t mean just clicking ‘Connect' on LinkedIn - it's always better to have in-person communications in order to build relationships. These are the advice I would give to my younger self.”

The School of Engineering at SFSU is overjoyed to hear about how Dr. Xiao is growing into her new position and we know she will continue to inspire students throughout the years.